- About Us

- Products & Services

-

START-UP PACKAGES & CASES

Add a Villa Dolce profit center to your business today. See more details about our Start-Up Packages!CUSTOM SOLUTIONS

For larger chains and institutional customers, Villa Dolce can develop a customized program that will delight your guests.FINE DINING

Our mission is to elevate dessert and convey a sensory experience through clean, natural, artisan recipes.FLAVORS

-

- About Us

- Products & Services

-

START-UP PACKAGES & CASES

Add a Villa Dolce profit center to your business today. See more details about our Start-Up Packages!CUSTOM SOLUTIONS

For larger chains and institutional customers, Villa Dolce can develop a customized program that will delight your guests.FINE DINING

Our mission is to elevate dessert and convey a sensory experience through clean, natural, artisan recipes.FLAVORS

-

- Resources

- Contact Us

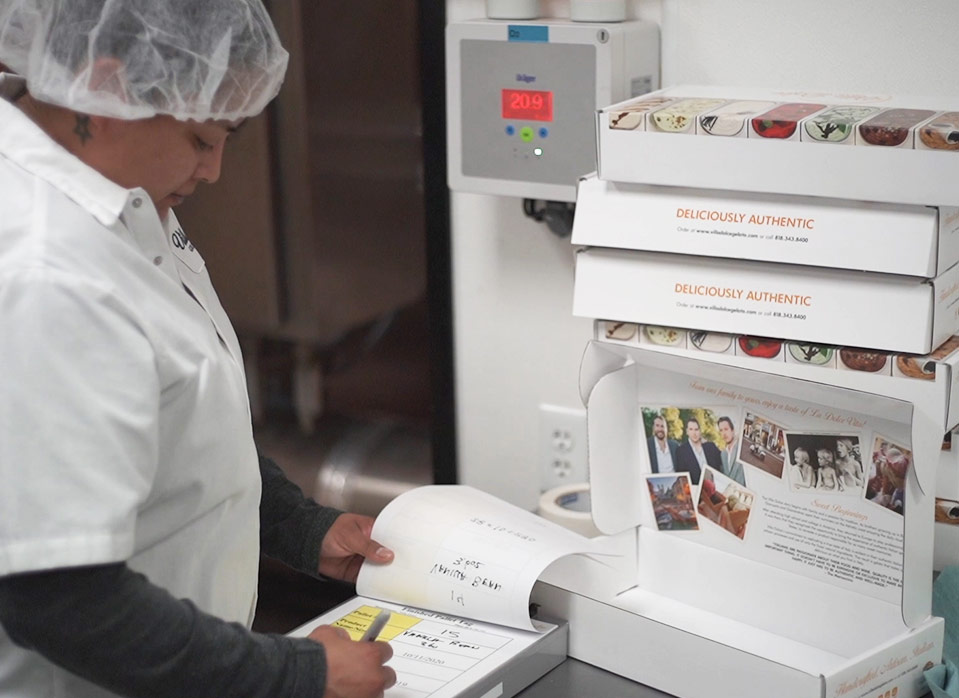

Food Safety & Production

DELIVERING THE HIGHEST POSSIBLE STANDARDS OF GLOBAL FOOD SAFETY

Villa Dolce is certified by Safe Quality Foods (SQF) to meet the GFSI requirements. The SQF family of food safety and quality codes are designed to meet industry, customer, and regulatory requirements for all sectors of the food supply chain – from the farm all the way to the retail stores.

This rigorous farm-to-fork food safety and quality certification helps assure our customers that our products meet the highest possible global food safety standards.

Certified Organic Facility

Our facilities are certified organic, enabling us to create Certified Organic products for our consumers.

Quality Management System

Our Quality Management System is the platform that we use to guarantee food safety, compliance with quality standards and to create value for consumers.

Villa Dolce requires tests and quality control checks at multiple stages of the manufacturing process and independent, third-party testing of our products for validation purposes.

Manufacturing Facilities

We understand that where things come from and how they are made is important. We honor the past by using traditional, artisan techniques and create value by combining them with modern technology.

Villa Dolce operates a state-of-the-art manufacturing plant in Phoenix, AZ, and a smaller boutique facility in Los Angeles, CA. To ensure the consistency and quality of every serving, our SQF certified, HACCP-run facilities combine old-world recipes, imported Italian equipment and time-honored, artisan techniques with the latest in manufacturing technology.

Nitrogen Tunnel

We are one of the few manufacturers to use a nitrogen tunnel, which flash freezes the water molecules before they have a chance to expand, further enhancing the creamy texture that is synonymous with gelato.

This process also helps our gelato maintain its artisanal presentation, saving our customers time and expense.

Let us help bring only the best to your table.

“At Villa Dolce, we are proud that our quality and safety standards meet or exceed all federal regulations and internationally recognized standards. We set the highest standards for ourselves and vendors.”

– The Marcaccinis